Week of January 16

January 15, 1876 – 150 YEARS AGO

Rockland County Journal

AROUND HOME

☞ Young ladies, remember this is leap year. There are several young men in the vicinity of our office looking forward to the future in deep contemplation.

☞ S. Schwarz, of Paterson, has recently purchased the farm of the late John S. Taylor between Monsey and Spring Valley, for the sum of $2,800.

☞ Owing to there being no snow for the boys to ride down hill, the crop of broken limbs, smashed noses and cut ears is not so large as it was last Winter.

☞ The Christmas Tree celebration of the Monsey Union Sabbath-school on New Year’s eve was well attended. The recipients of the presents seemed highly delighted.

☞ The Monthly Concert of the Monsey Union Sunday-school, on Sunday evening last, was largely attended, and much interest seems to be manifested by those who attend.

January 16, 1926 – 100 YEARS AGO

Rockland County Times

BRICK IN THE MAKING — In Its Making Lies the Secret of Its Beauty and Durability; Seventy-eight Steps Transform the Raw Clay into a Building Unit — Haverstraw’s Most Famous Product — Most Durable Building Material

Probably everyone has passed many a building operation and noticed the familiar red brick being laid by the equally familiar bricklayer. Almost as great a number have unconsciously assumed that a brick, like Topsy, “just grew,” whereas the history of the manufacture and use of this every-day article is of absorbing interest. The record is continuous for more than forty-one centuries and records of as early a date as 5,400 B.C. mention it as a building material. One could safely say that the story of brick is analogous to that of civilization.

Webster defines brick as “a building and paving material made from clay (either pure or

mixed, as with sand, lime, etc.) by making into blocks while moist and hardening it by the

sun or by fire,” . . .

Among builders of today brick means a rectangular oblong 2 ¼ × 3 ¾ × 8 of clay, burned at a high temperature and red in color. Although there have been many improvements in methods in proportioning ingredients, molding, firing, transportation, etc., since the introduction of brick as a building material, the principles of manufacture and use show little, if any change. Since Haverstraw began the making of brick by the Wood family about where Taylor’s Garage is now located, except the drying as shown by the Satlet system of the Fowler yards and the steam dryers of the Ganer Brick Co. Innumerable attempts to produce synthetic brick have been made and a few have met with, moderate success, but the original burned clay brick is still recognized as the popular and dependable product.

Altogether there are seventy-eight operations in the transposition from raw clay in the bank to the finished article forming part of the building, but only a brief description of the more important of these will be mentioned. The raw clay, dug now, in some instances by steam shovels, is transported to a mixing pit, where it is tempered with a small quantity, of sand, and, in some cases, an even smaller amount of coal dust to facilitate combustion in the kilns. The tempered clay then passes by conveyors to the brick machine, where a number, usually six, brick are molded at one time and discharged automatically to a second conveyor. The brick machine not only forces the mixed clay into the molds, but dusts the form with molding sand, introduces coloring, if used, and finally delivers the brick on a steel platform or pallet to the conveyor. In turn the conveyor carries these pallets with their load of “green” brick to the point where the brick are dried until sufficiently hard for handling. There are three principal methods of drying and the yards are designed as “dryer yards,” where this operation is accomplished in steam-heated buildings; pallet yards,” where the green brick is laid on the ground without protection from storms. In the last mentioned type of plant both sun and air are relied upon to harden the product.

The next step is the burning of the brick in huge kilns, containing as many as 1,000,000 each. On the Hudson River each kiln is individually built of brick so laid that heat, introduced through “arches” running transversely through the bottom, can penetrate the entire kiln. The sides and ends are covered with wet clay to prevent the escape of heat, only the top remaining open for a vent. Although in a very few plants wood is still used, practically all brick is now burned with either coal or oil. This process requires exceptional skill, as a constant temperature must be maintained for a period of about seven days. Upon completion the kiln is allowed to cool and then is opened, displaying a product now ready for sorting previous to shipment. Each kiln contains a certain proportion of over-burned brick, those coming in direct contact with the flames, which are sorted out, only the perfect brick being loaded on barges or cars for shipment to market for the regular trade. As certain architectural effects are obtainable only through the use of these over-burned units, there is a considerable demand for them as, due to unevenness of the surface, additional handling is necessary, the cost of what some might call “seconds” is more than that of the regular product.

Weight and Strength

The standard Hudson River brick weighs about four pounds and has a crushing strength of some 4,400 pounds a square inch when tested flat; on edge the strength is considerably greater.

The building code of New York City requires that brick masonry be so designed that the loading shall not exceed 250 pounds a square inch, in order to provide what engineers term a sufficient factor of safety. New York City consumes about one billion brick a year, requiring 221 barges, each carrying an average of 400,000 brick, to transport the material. This is in addition to rail shipments.

The use of common brick for exteriors is increasing rapidly, due not only to its low cost, but to the infinite variety of effects which can be obtained. As our well-known designer expressed it: “A common brick wall is like looking at a wood fire with its innumerable color combinations. Each glance reveals a new and previously unseen effect, and it is impossible to say which of the many is the most beautiful.”

The fact that brick, in its manufacture, is burned at such high temperature accounts for its resistance to fire and it is a matter of common knowledge that its ability to withstand the assaults of weather is second to no other material.

Common brick is a commodity, like sand and gravel, that is produced for more or less local markets. Hudson River common brick movements into New York City would therefore reflect an important side of the building market.

In 1925, therefore, 2,004 barge loads of Hudson common brick came to New York City for local building construction. The highest previous record was in 1905 when 3,589 came in.

Here, exclaims Sound Business, is an exception to the production records of other lines. But the common brick manufacturer quickly reminds him that the brick barge of 1905 and of 1912 carried only 300,000 brick each. Barges of today float as high as 600,000 each.

January 15, 1976 – 50 YEARS AGO

The Journal News

PAMPHLET PUBLISHED — RECALLING NEW CITY’S PAST

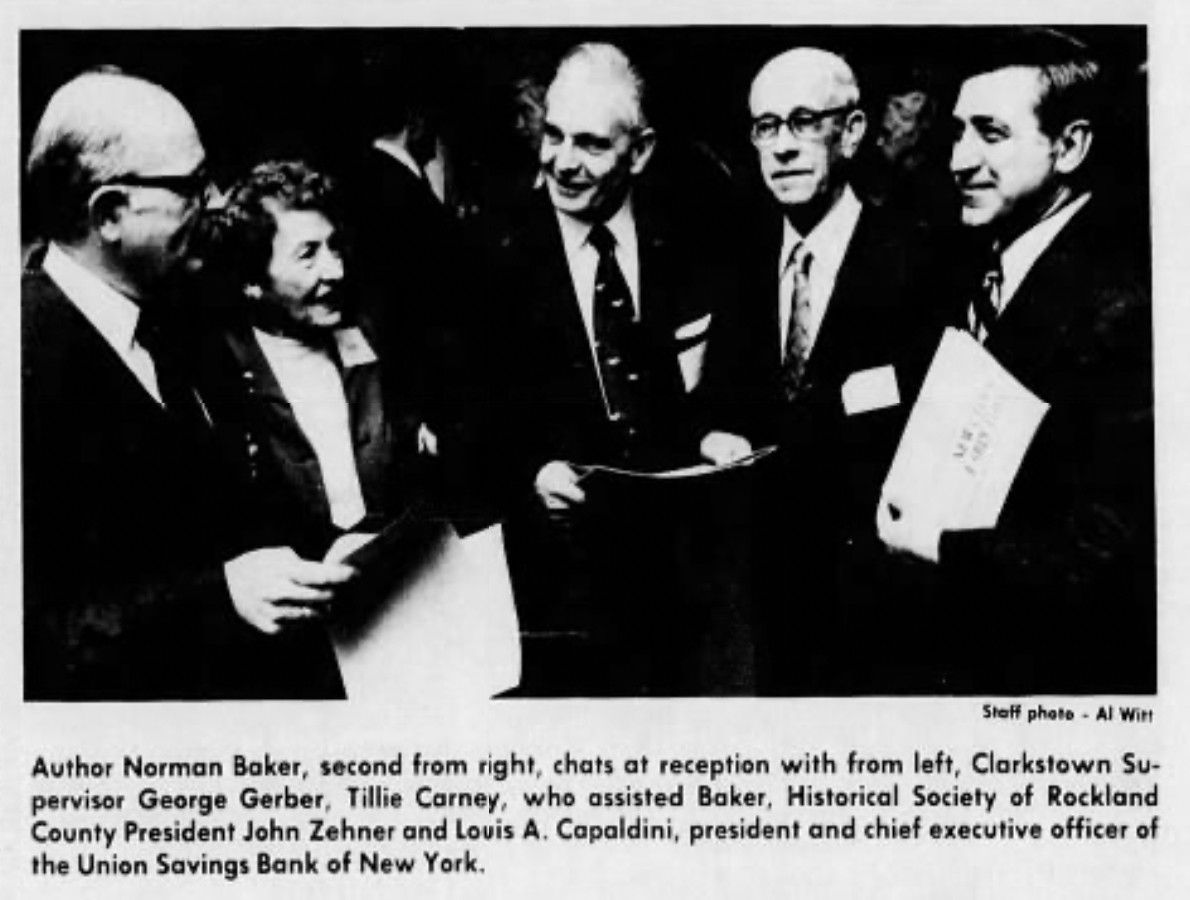

[Image: Author Norman Baker, second from right, chats at reception with from left, Clarkstown Supervisor George Gerber, Tillie Carney, who assisted Baker, Historical Society of Rockland County President John Zehner and Louis A. Capaldini, president and chief executive officer of the Union Savings Bank of New York. Journal News staff photo by Al Witt.]

“When I was a kid, there were 300 people in New City,” Norman Baker recalled Wednesday. “If anyone had told me that in 60 years there would be 300,000 people here, I would have told him he was crazy.”

Fortunately for Baker, no one at the time made that prediction and he does not have to eat his words today. In the last 60 years, the face of New City has changed radically, and Baker, who has lived in the hamlet since 1906, has become its most prominent historian.

In a pamphlet entitled “New City’s Early Days,” Baker described the hamlet as it was when farming was the primary occupation of its residents, and horse and wagon were the primary means of transportation.

The pamphlet is being published and distributed by the Union Savings Bank, located on Main Street in the hamlet. A ceremony at the bank Wednesday attended by about 100 county leaders officially dedicated the booklet.

The guests included, among other dignitaries, District Attorney Kenneth Gribetz, Ramapo Supervisor Morton Baron, judges John Gallucci and Robert Stolarick and County Sheriff Raymond Lindemann. Clarkstown Supervisor George Gerber thanked the bank for its support on behalf of the town.

Printed on simulated parchment paper, the 18-page chronicle, through its text and pictures, reveals a glimpse of the New City of old. About 2,000 will be distributed to interested individuals, libraries, schools and realtors.

The project was initiated by the bank as part of its effort to create a historical record in each area where its banks are located. Each project is developed to take advantage of the character and resources available in the community, according to Louis Capaldini, the bank’s president.

In the case of the New City booklet, the prime resource was Baker’s more extensive work, entitled “New City: The Way It Was.” Much of the text in the new pamphlet has been taken from the earlier booklet.

The 74-year-old retired editor of The Journal-News recalled Wednesday that even in 1907, commuting to New York City was a common practice among hamlet residents. His father, an assistant district attorney in Brooklyn, did it every day.

“It was quicker to commute to the city than it is today,” he said. By train, ferry and trolley, his father could leave home at 7:15 a.m. and be in the office before 9.

This Week in Rockland (#FBF Flashback Friday) is prepared by Clare Sheridan for the Historical Society of Rockland County. © 2026 by The Historical Society of Rockland County. #FBF Flashback Friday may be reprinted only with written permission from the HSRC. To learn about the HSRC’s mission, upcoming events or programs, visit www.RocklandHistory.org or call (845) 634-9629.